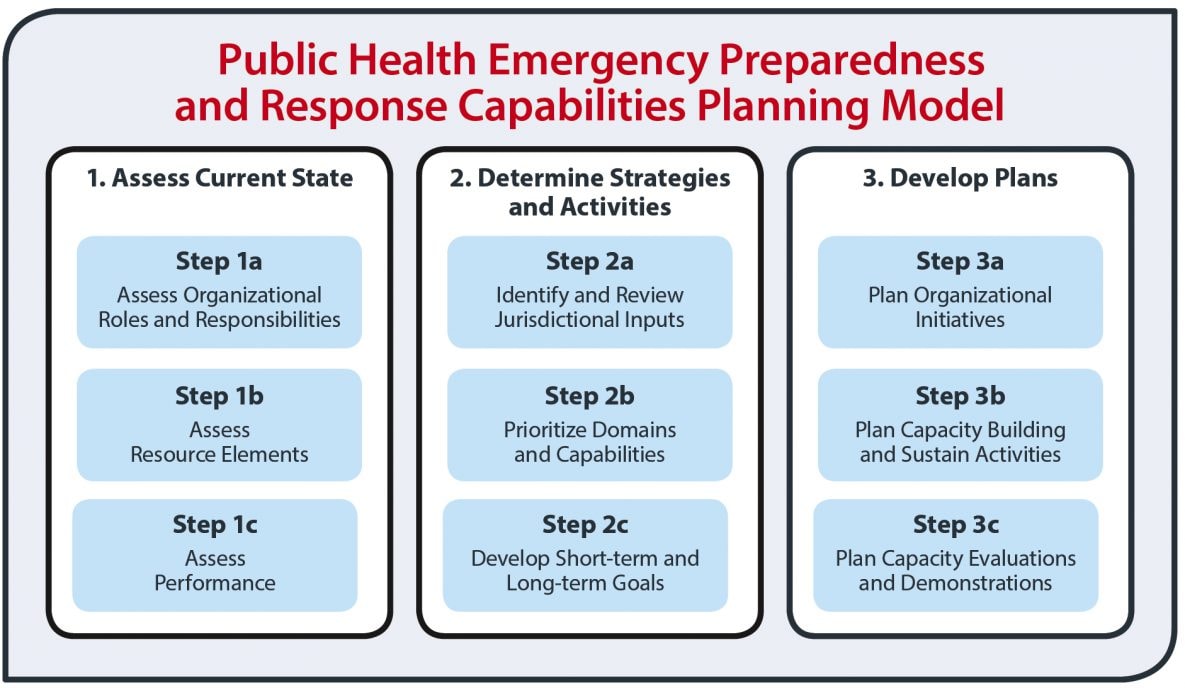

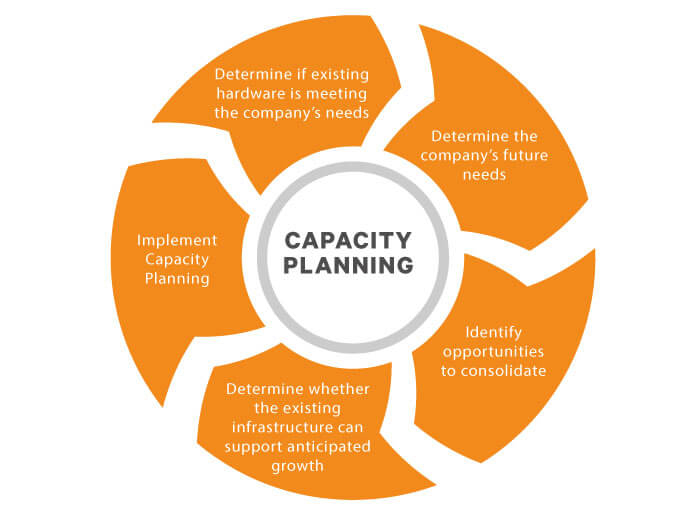

Such capabilities are the product of system‐ and organisational‐level capacities, a competent workforce, and a defined and practised preparedness plan 18 (2)Level capacity plan definition What is level capacity strategy The definition in Capacity Development in Practice is "Capacity is the ability of a Capacity and production planning involves meeting the future needs for your products without accumulating excess inventory Before you can implement such a plan

Capacity Management

Level capacity plan

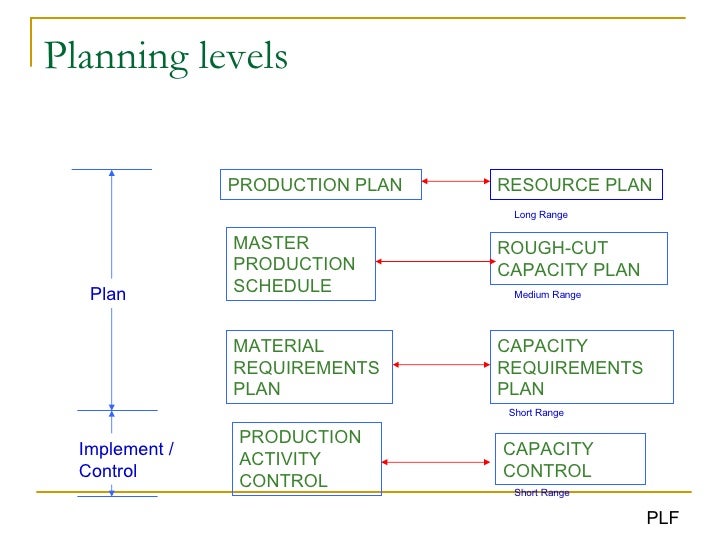

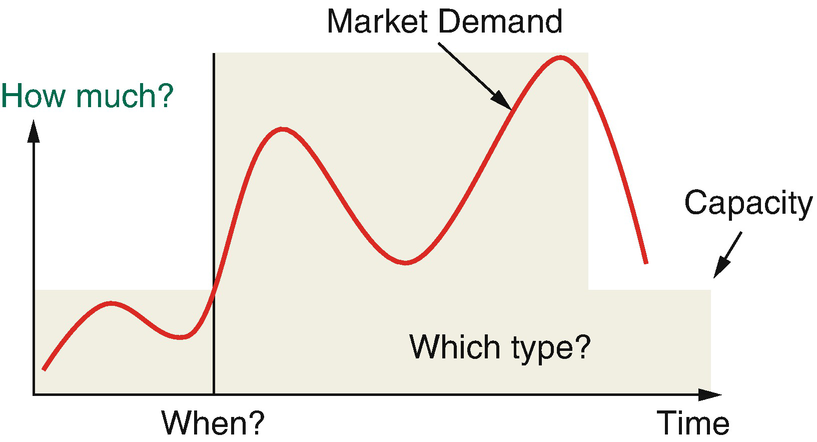

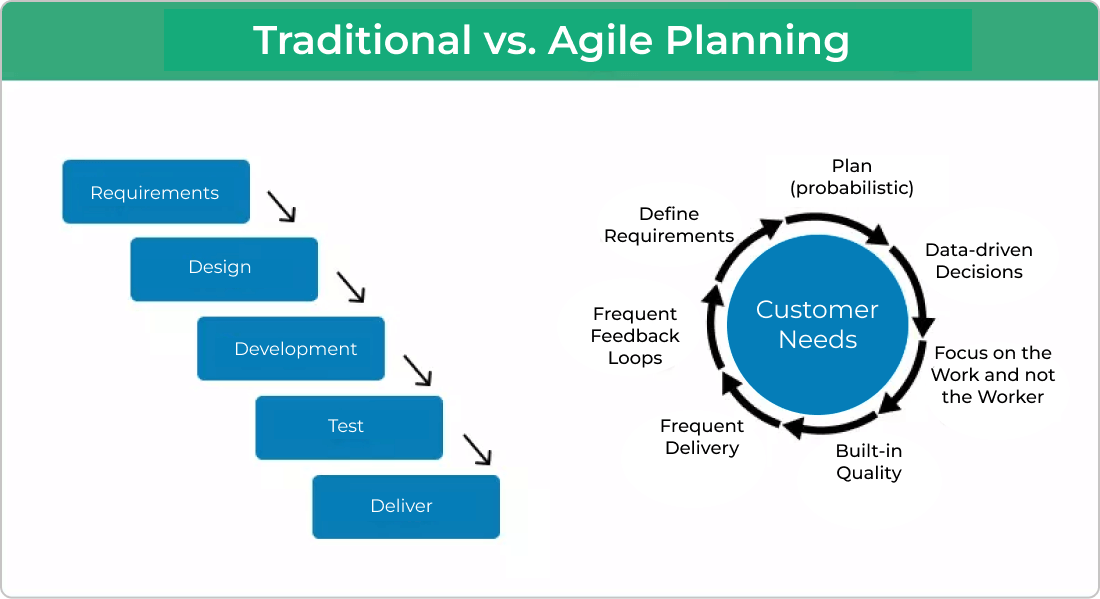

Level capacity plan- Capacity planning is longterm decision that establishes a firm's overall level resources It extends over a time horizon long enough to obtain resources Capacity One approach to leveling (also known as heijunka 平準化, or production smoothing) is capacity leveling Do not add more production orders into the system than what the

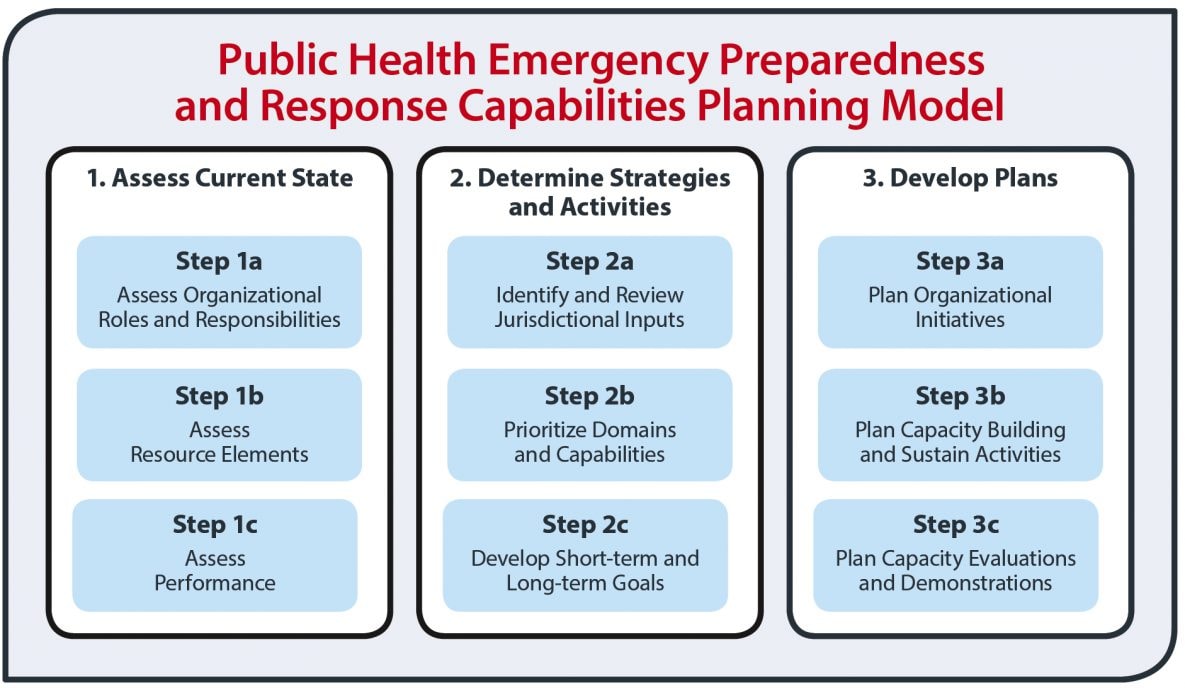

Public Health Preparedness Capabilities National Standards For State And Local Planning State And Local Readiness Cdc

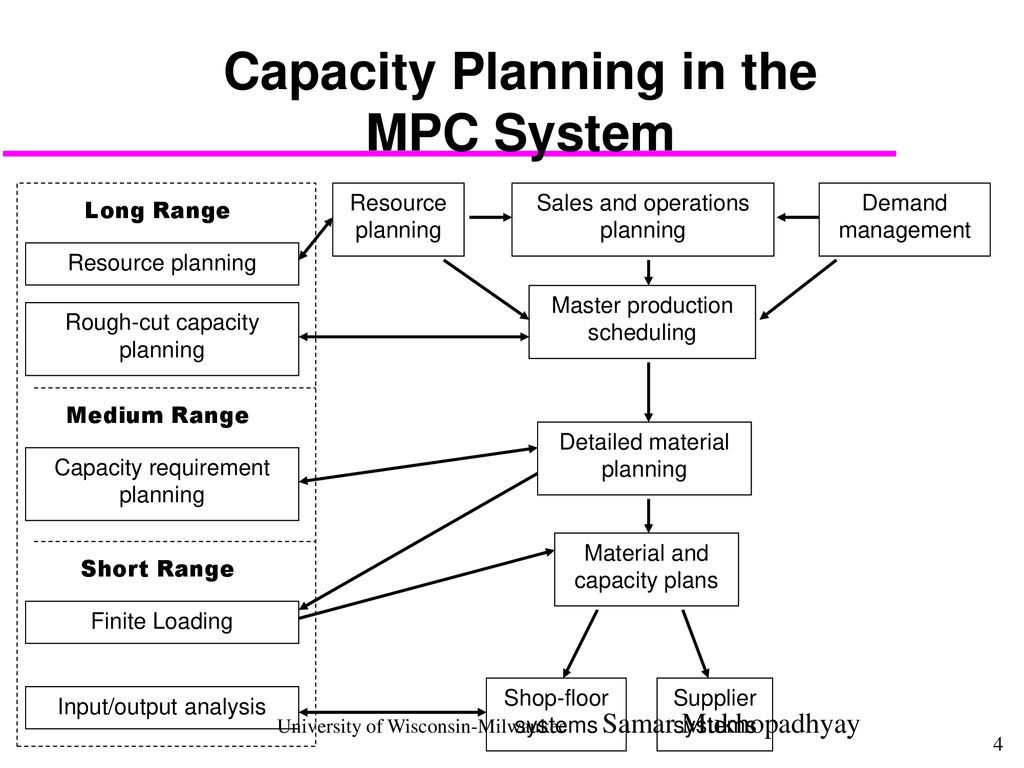

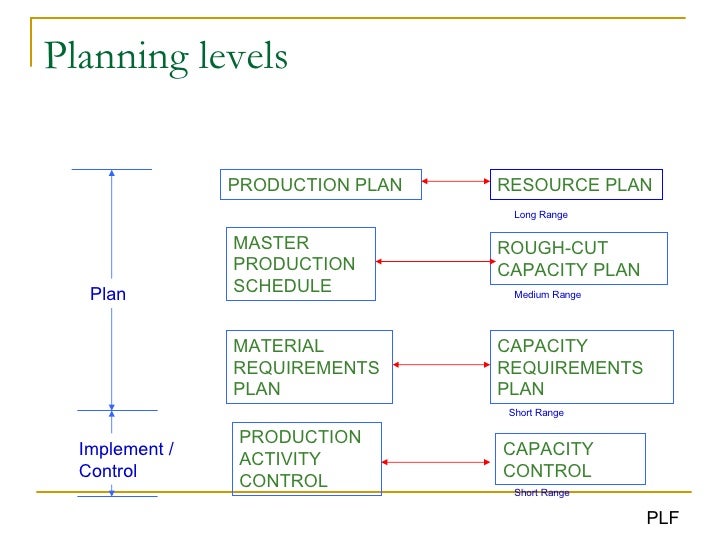

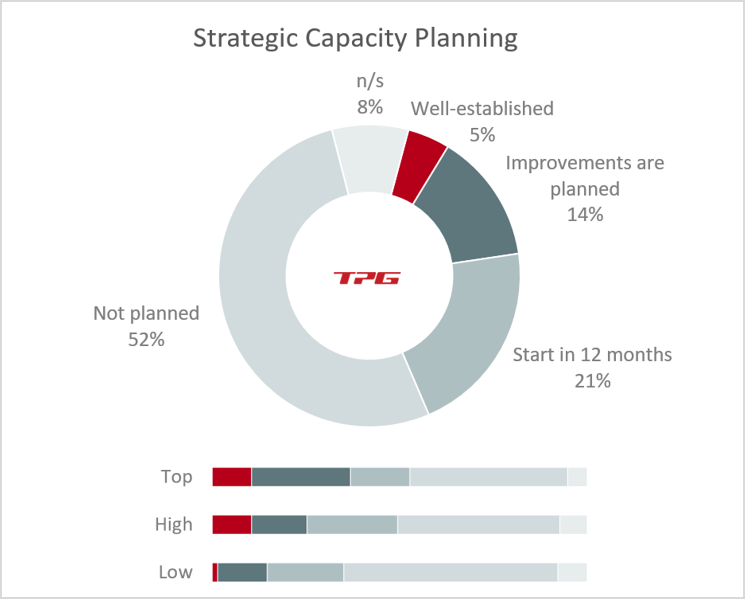

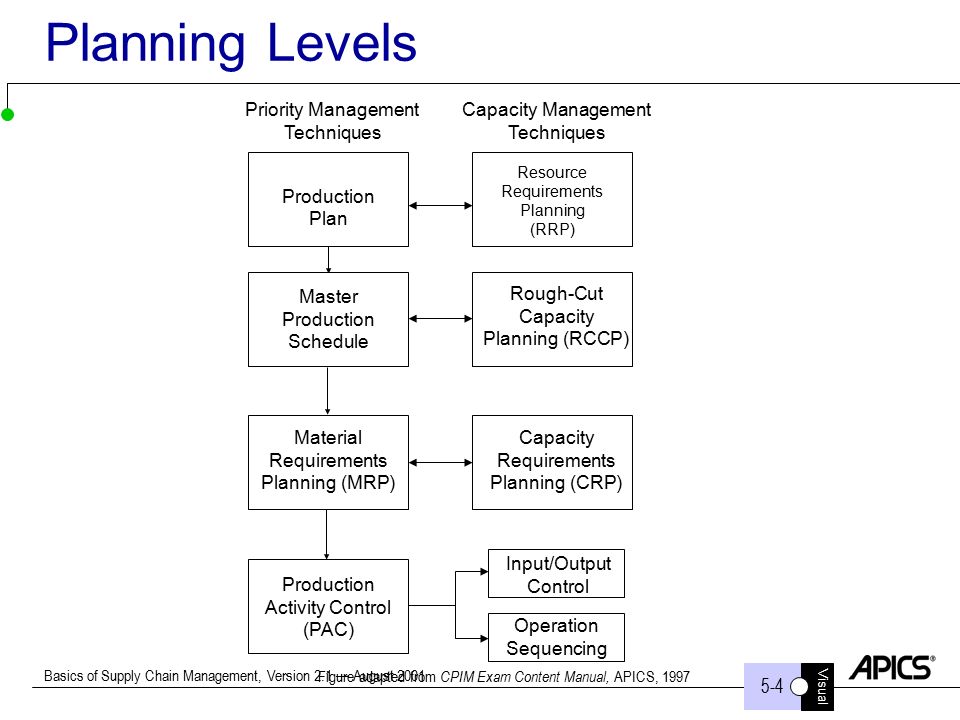

Overview of Rough Cut Capacity Planning (RCCP) RCCP verifies that you have sufficient capacity available to meet the capacity requirements for your masterStrategic capacity planning is essential as it helps the organization in meeting the future requirements of the organization Planning ensures that operating costCAPACITY PLANNING Capacity can be defined as the maximum output rate that can be achieved by a facility The facility may be an entire organization, a division, or

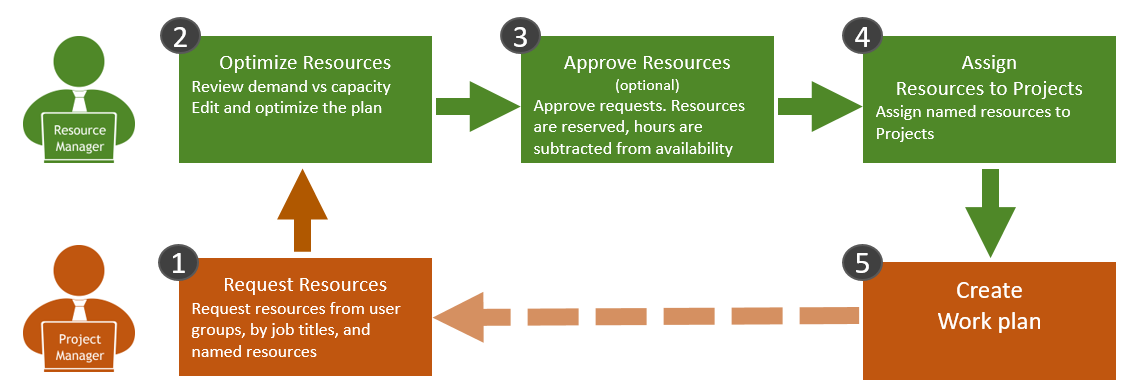

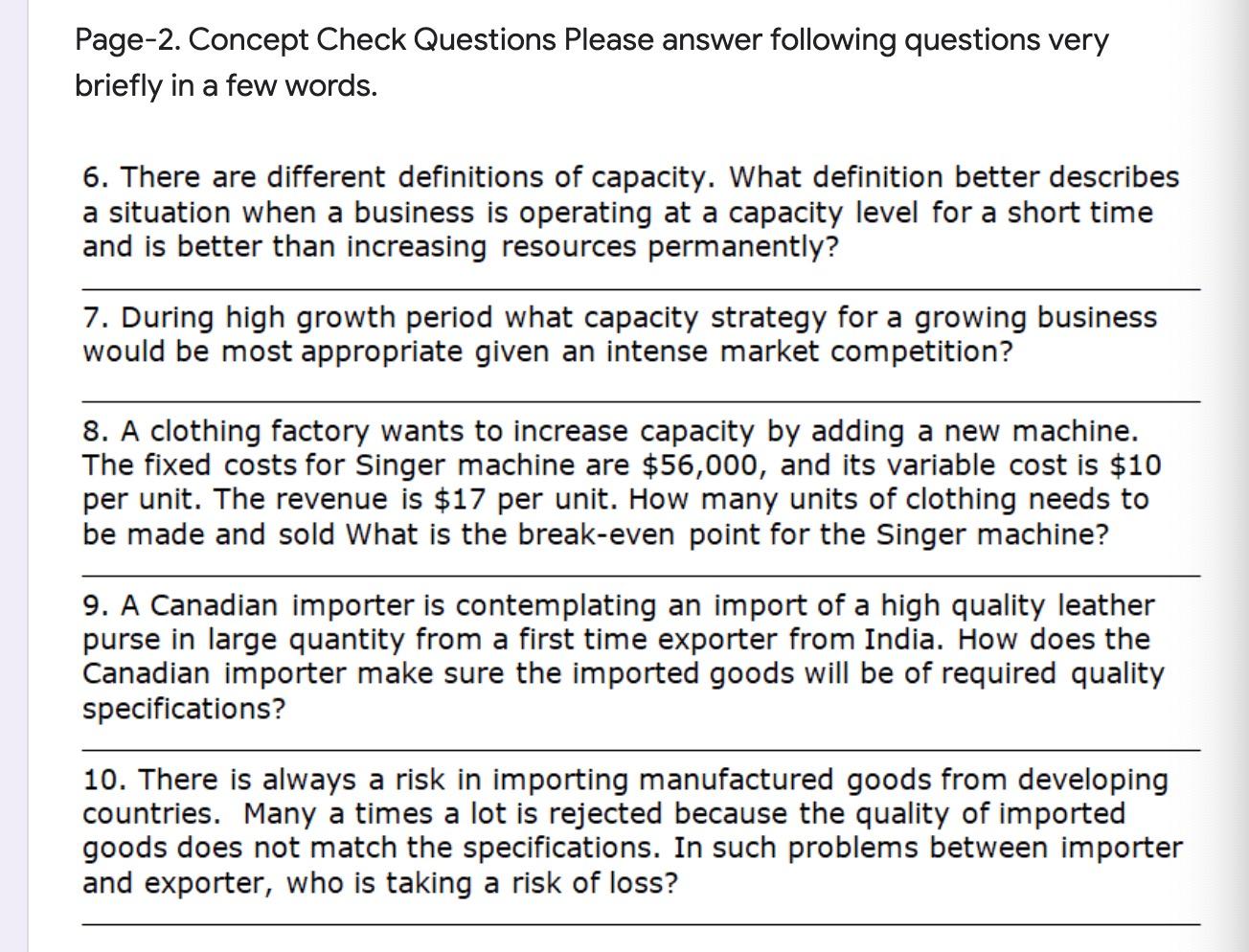

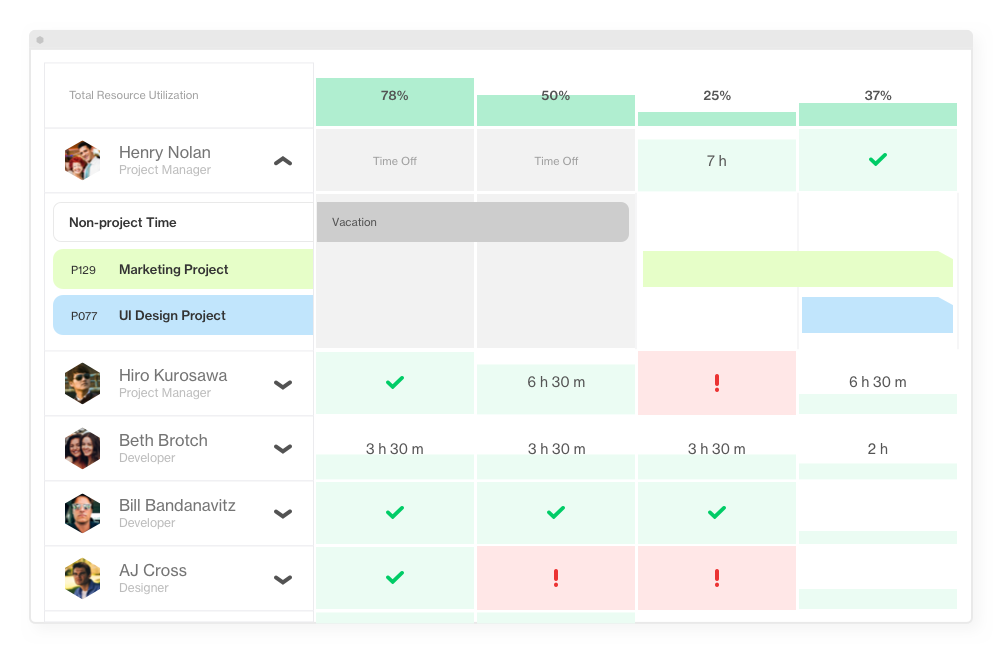

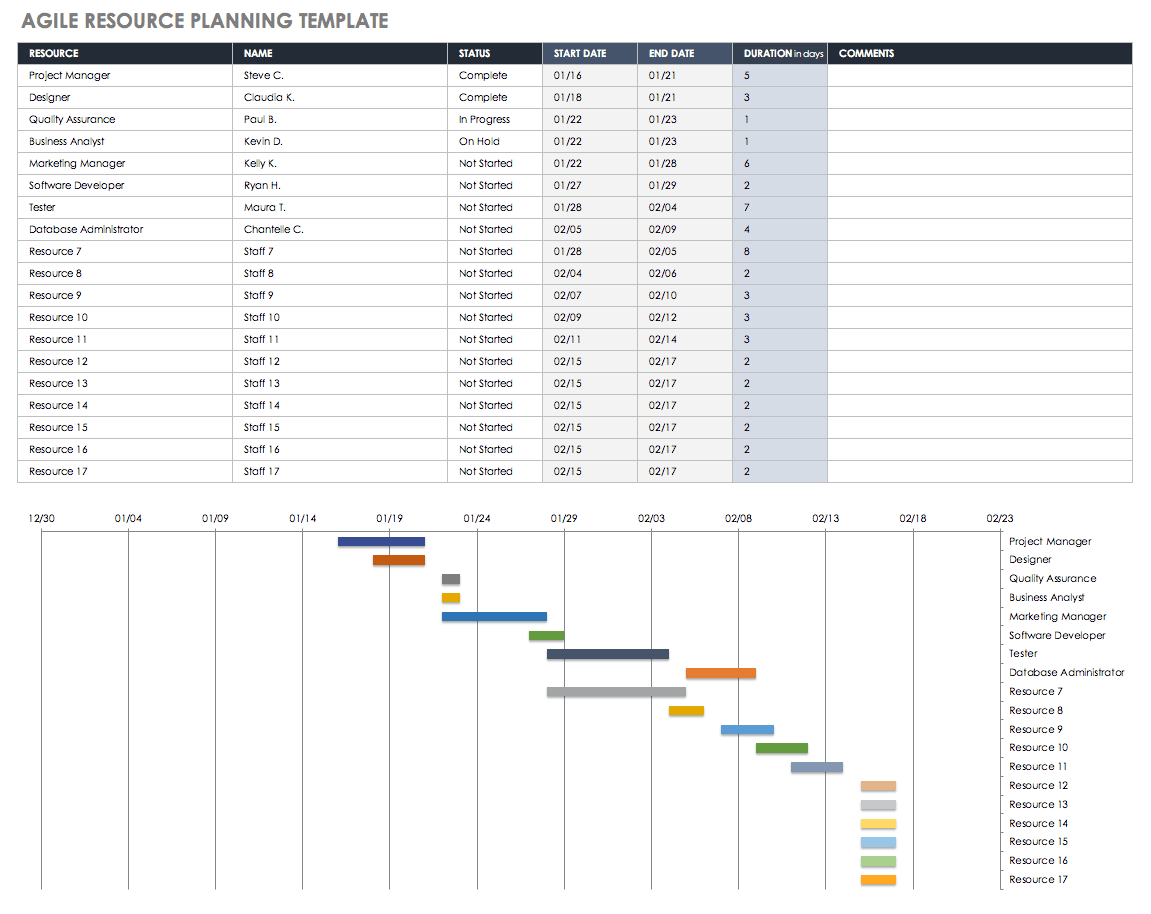

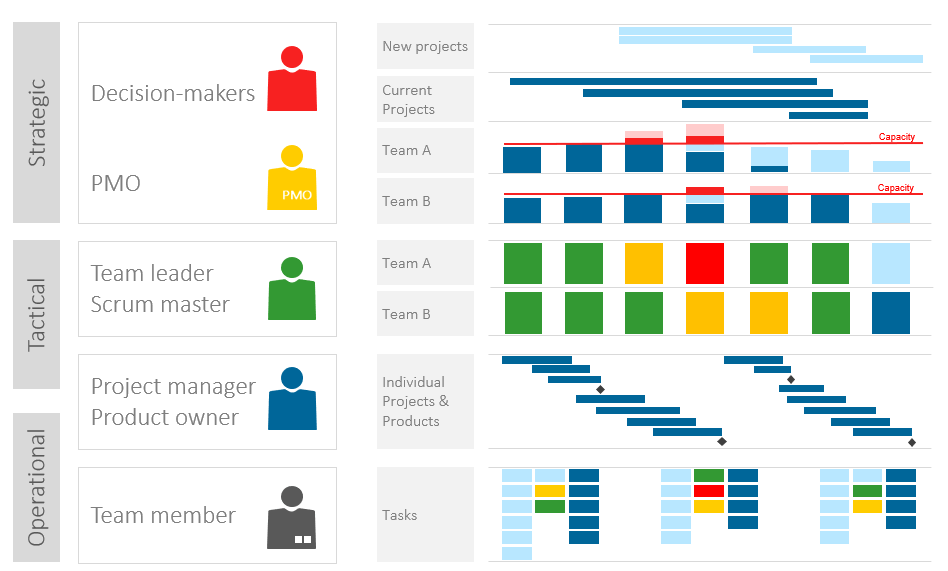

Resource capacity planning is a tool used to determine the resources needed by an organization in order to meet future workflow demands that stem from the need to1 Capacity decisions have a real impact on the ability of the organizationto meet future demands for products and services 2 Capacity decisions affect operating Capacity planning is high level and strategic To keep your capacity planning simple, you need to analyze your capacity plan at the team or skill level and not by

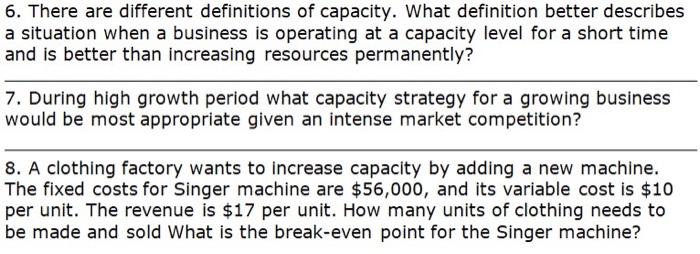

John Spacey, Capacity management is the process of planning the resources required to meet business demands This includes capacity forecasting, planning Capacity planning is a process that balances the available hours of teams against what the project needs Capacity, in this case, is the most work that can be doneCapacity requirements planning (CRP) is the process of discerning a firm's available production capacity and whether it can meet its production goals

6 There Are Different Definitions Of Capacity What Chegg Com

Chapter 7 Capacity Planning And Management Ppt Download

Capacity Planning Version associated with either underutilized resources or unmet customer demand and to provide satisfactory service levels in a "Capacity Planning is the process of determining the production capacity needed by an organization to meet changing demands for its products" Wikipedia in EnglishCapacity planning can be challenging for organizations of any size It requires a delicate balance between realtime employee availability, available dollars in the

Business Capability Map And Model The Definitive Guide Leanix

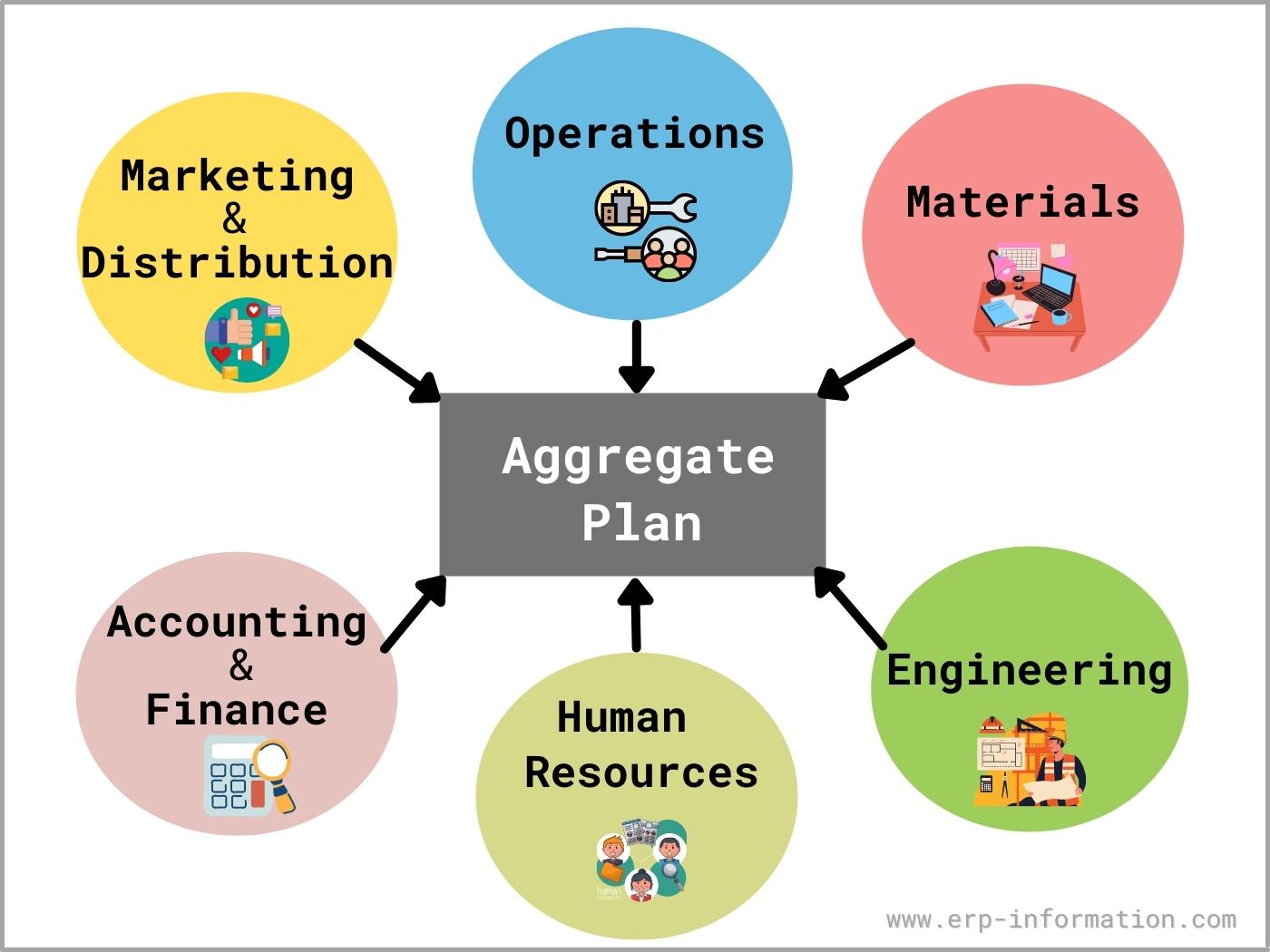

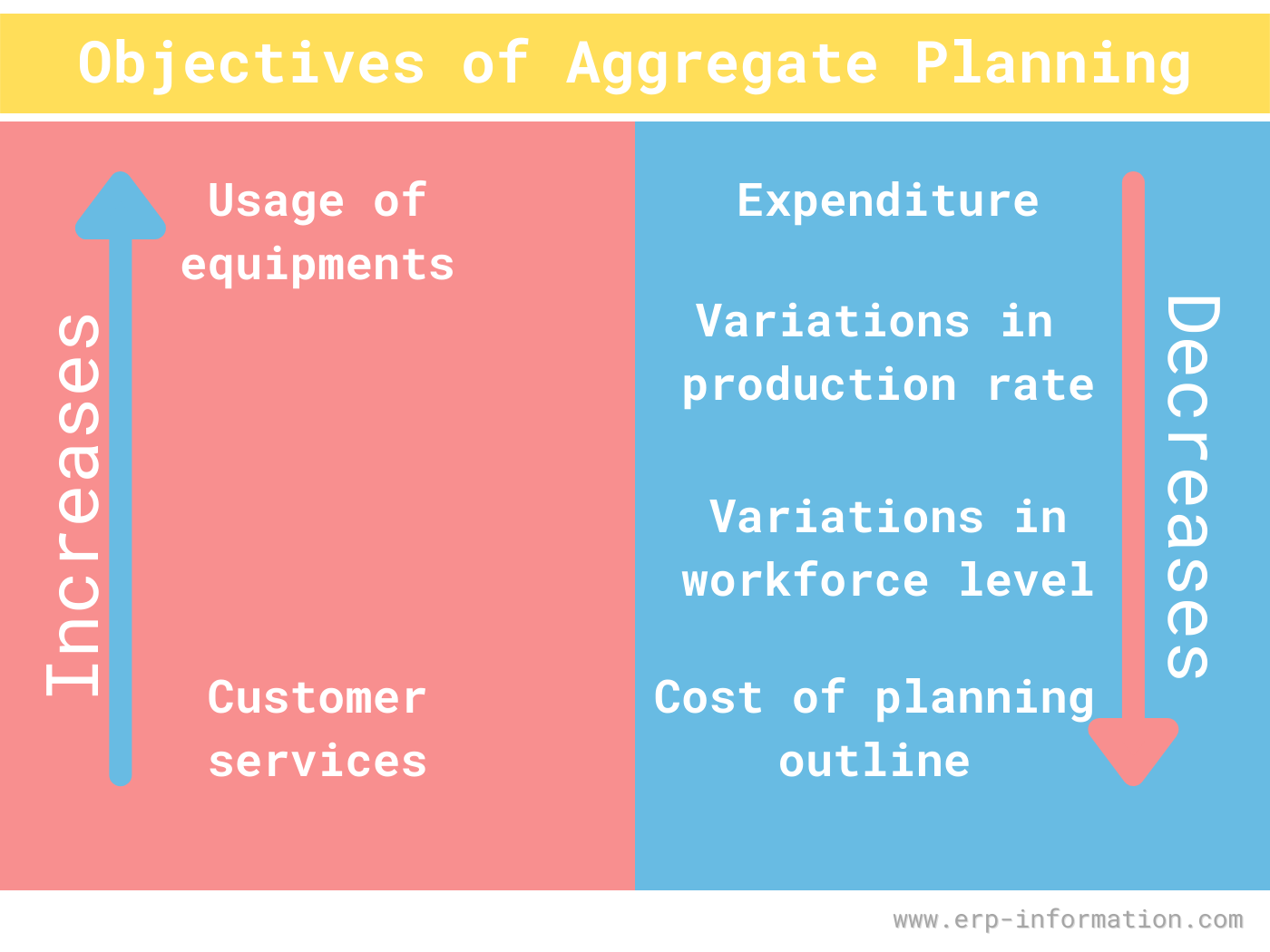

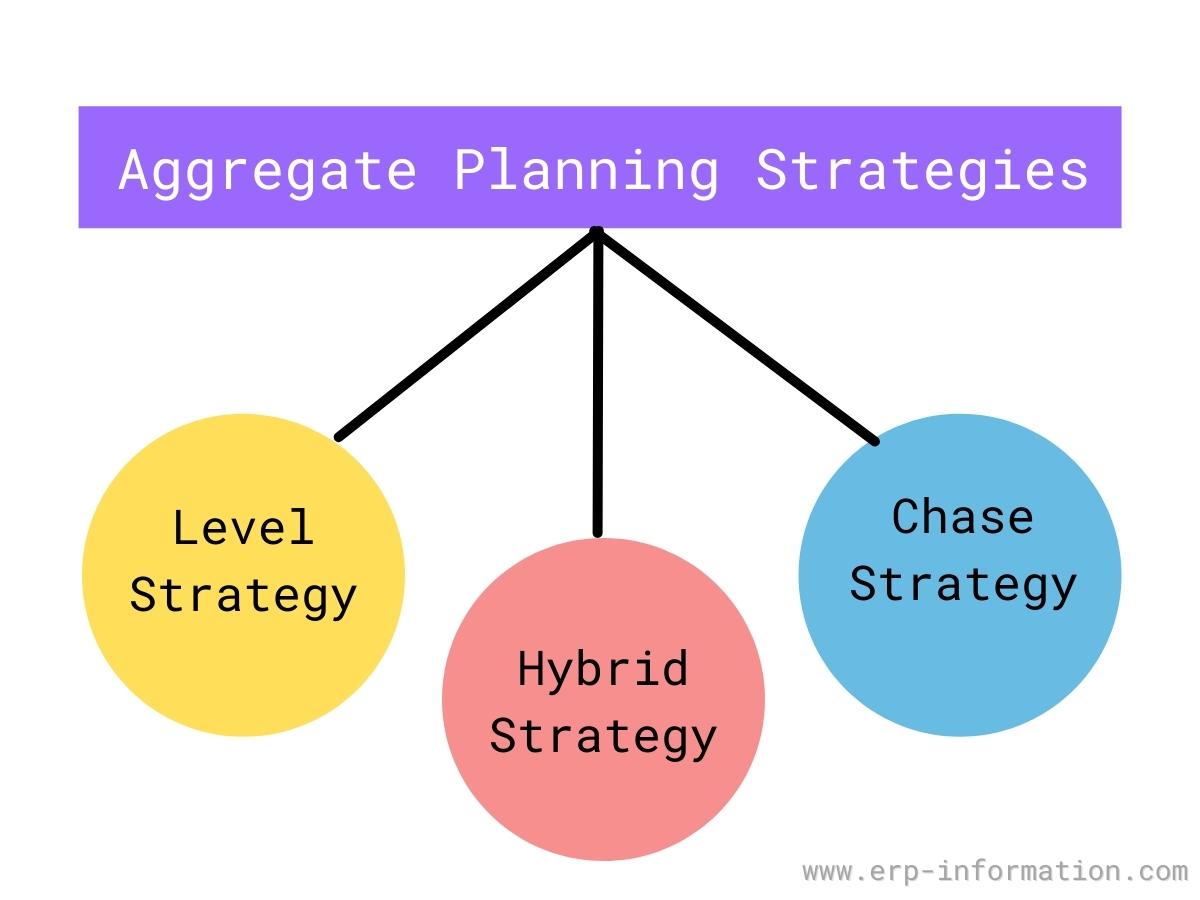

What Is Aggregate Planning 3 Strategies For Aggregate Production Planning

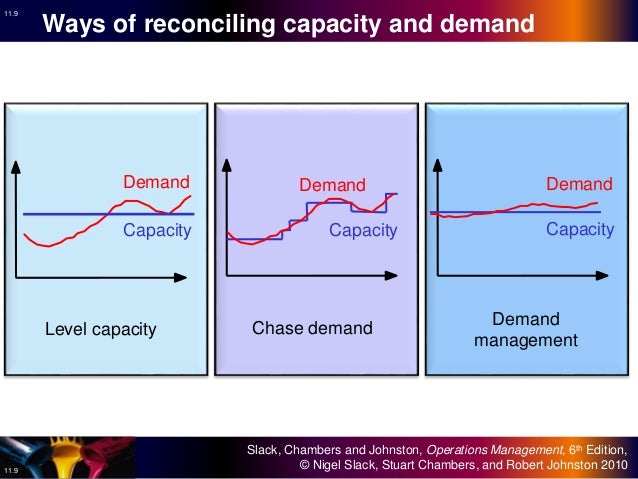

Operation Management Assignment Help, Explain about the level capacity strategy, Explain about the level capacity strategy Level capacity strategy The Capacity planning is concerned with defining the longterm and the shortterm capacity needs of an organization and determining how those needs will be satisfiedCapacity Planning refers to the arrangement in which organizations or teams match employees together with the needs of a project Capacity

Capacity Planning Organization System Examples Definition System Long Term Capacity Planning

11 Capacity Planning And Control Operations Management

THREE STEPS OF CAPACITY PLANNING 18 Determine Service Level Requirements 19 The first step on the capacity planning process is to categorize the work done by 5 Examples of Capacity Analysis John Spacey, Capacity analysis is the process of modeling the capacity of infrastructure, facilitiesCapacity levels for the planning period The second step will be to identify the alternative capacity plans which could be adopted in response to demand

3

Capacity Planning Everything You Need To Know Opensense Labs

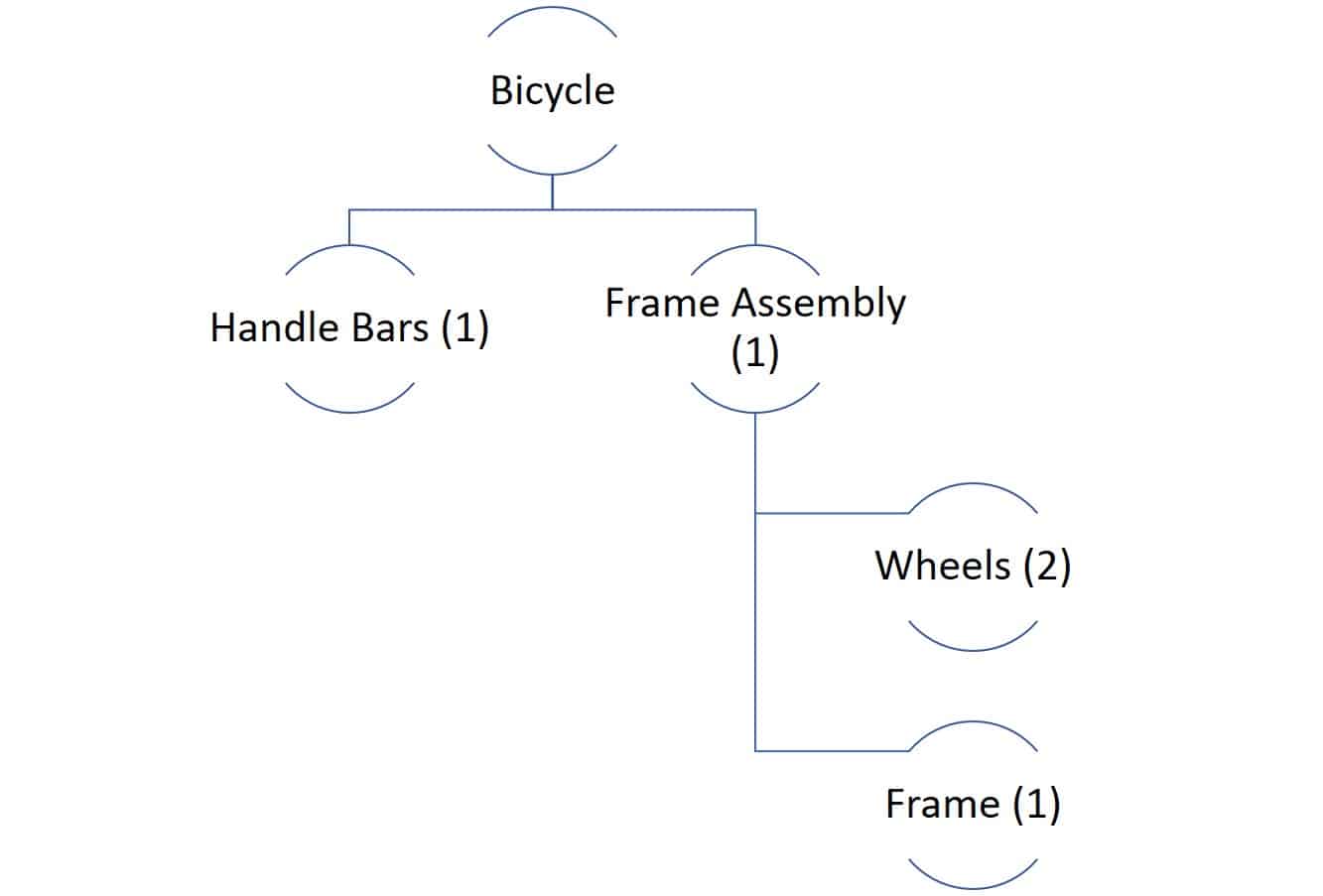

Product capacity planning Product capacity planning ensures that you always have enough raw materials and products needed to complete an order Raw materialLongrange capacity planning is the process of ensuring that sufficient production resources (facilities, people, equipment, and operating hours) are available to meet Definition a graphic comparison of each work center's available capacity and the load established by the planned and released orders for each time period of the

1

It Management Processes Ibm Model Download Table

Lead Strategy An upfront investment in more capacity that you need This can be done when capacity is inexpensive or difficult to obtain For example, a new vineyard Capacity planning is the practice of planning/determining production capacity and workforce needs to make sure your supply chain is equipped to meet demand Capacity capacity planning In information technology, capacity planning is the science and art of estimating the space, computer hardware, software and connection

Capacity Planning V3 Mgmt 3154 Studocu

Production Planning Wikipedia

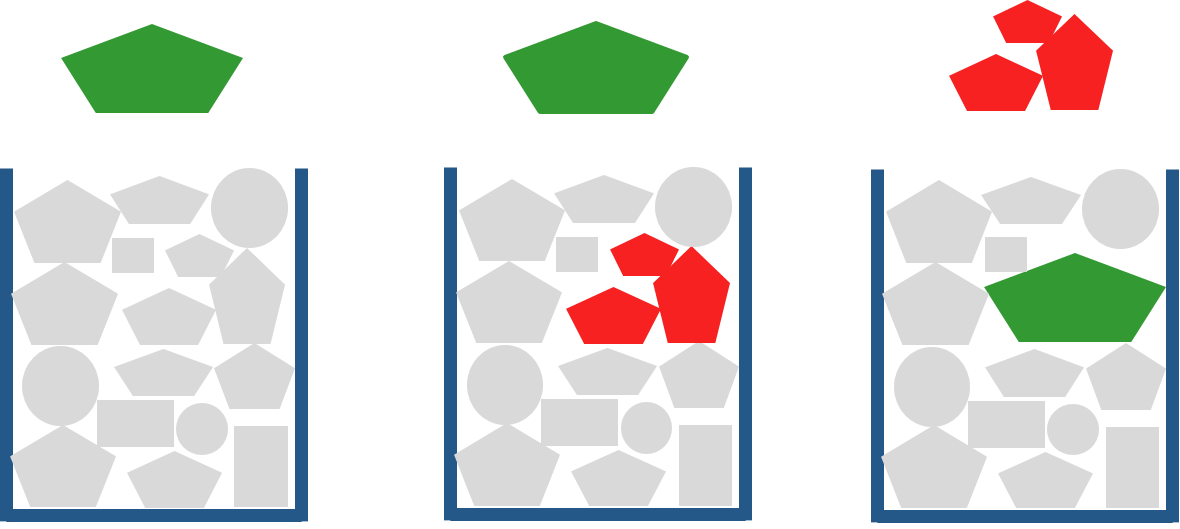

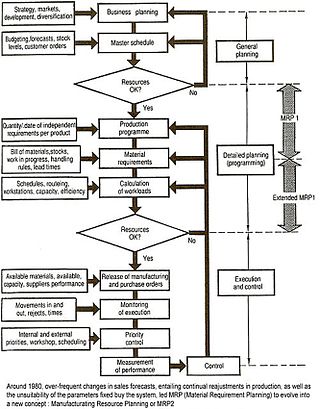

Figure Level Capacity Plan Figure shows the level capacity plan of a company manufacturing a product on produce to stock and sell basisCapacity Building • Capacity Building != training – Eg Consider The Waters of Ayole, only the mechanic was "trained" • 3 levels of ITbased people and processExhibit 117 shows how the components of MPC discussed in the definition interrelate Exhibit 117 Manufacturing Planning and Control As one moves from the top of

Production Planning Meaning Importance Steps Example Mba Skool

What An Effective Capacity Planning Process Looks Like In 21

Capacity planning is the process used by a business to determine the resources it will acquire to meet the demand for its products or services The more capacity aLevel capacity strategy The demand for any product is never constant It may change due to various reasons An operations manager has to plan in advance about theDefinition The Capacity Plan is used to manage the resources required to deliver IT services The plan contains scenarios for different predictions of business

Capacity Planning What Is It And How Do I Implement It Projectmanager Com

Capacity Planning How Much Long Range Capacity Is Needed When More Capacity Is Needed Where Facilities Should Be Located Location How Facilities Should Ppt Download

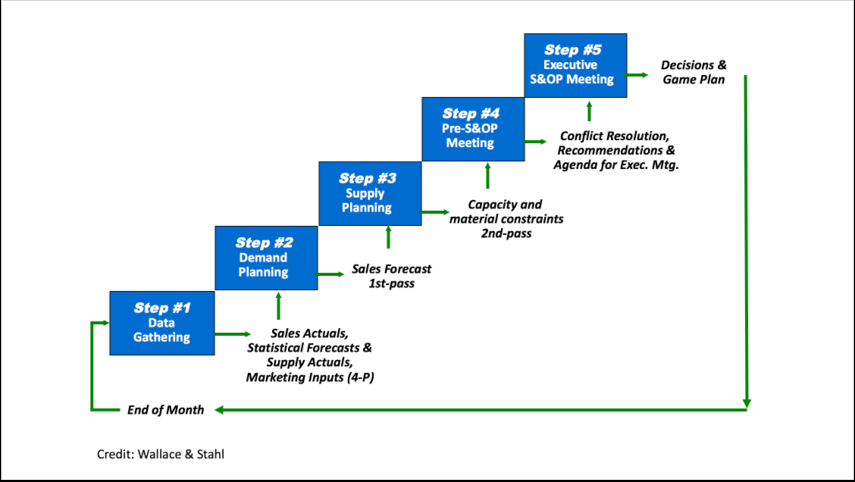

Process of capacity planning because the provide information on future demand Thus, the importance of forecasting to capacity planning cannot be overstated TheTop level planning technique to provide overall rates of sales and production, and backlog and finished goods inventory positions In a cellular or flowline basedCapacity planning at a company level Aligning project demand with your team's capacity is an essential part of project management efforts, but strategic

Capacity Planning Everything You Need To Know Clicktime

Aggregate Planning Definition Importance Strategies Management And Advantages

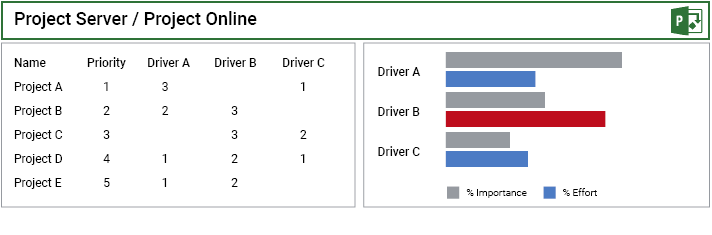

What is Capacity Planning?Capacity is usually planned on the basis of labour or machine hours available within the plant Thus, capacity planning is planning for quantity or scale ofEnterpriselevel capacity planning in project management software also allows executives to ensure their best resources are on their most critical projects Imagine

What Is Capacity Management Role In Planning Marketing91

Capacity Planning How Much Long Range Capacity Is Needed When More Capacity Is Needed Where Facilities Should Be Located Location How Facilities Should Ppt Download

Capacity to Make and Sell 4 Actual Capacity 5 Normal Capacity 6 Idle Capacity Plant Capacity Level Type # 1 Maximum Capacity This is the cent perCapacity Planning Unit Introduction Capacity Planning is vital in operations management with capacity It is important as it determines the optimal level ofUnder the chase strategy, production is varied as demand varies With the level strategy, production remains at a constant level in spite of demand variations The use

Bus300 Strategic Capacity Planning For Products And Services Saylor Academy

Difference Between Resource Planning And Capacity Planning

Capacity planning is defined as a method to gauge the production capacity needed to meet the changing product demands of an organization Two terms of design

Metron Capacity Management Capacity Management Guided Practitioner Satnav Capacity Plan 16 Of 17

Itil Service Management Itil Management Project Management Templates Project Management Change Management

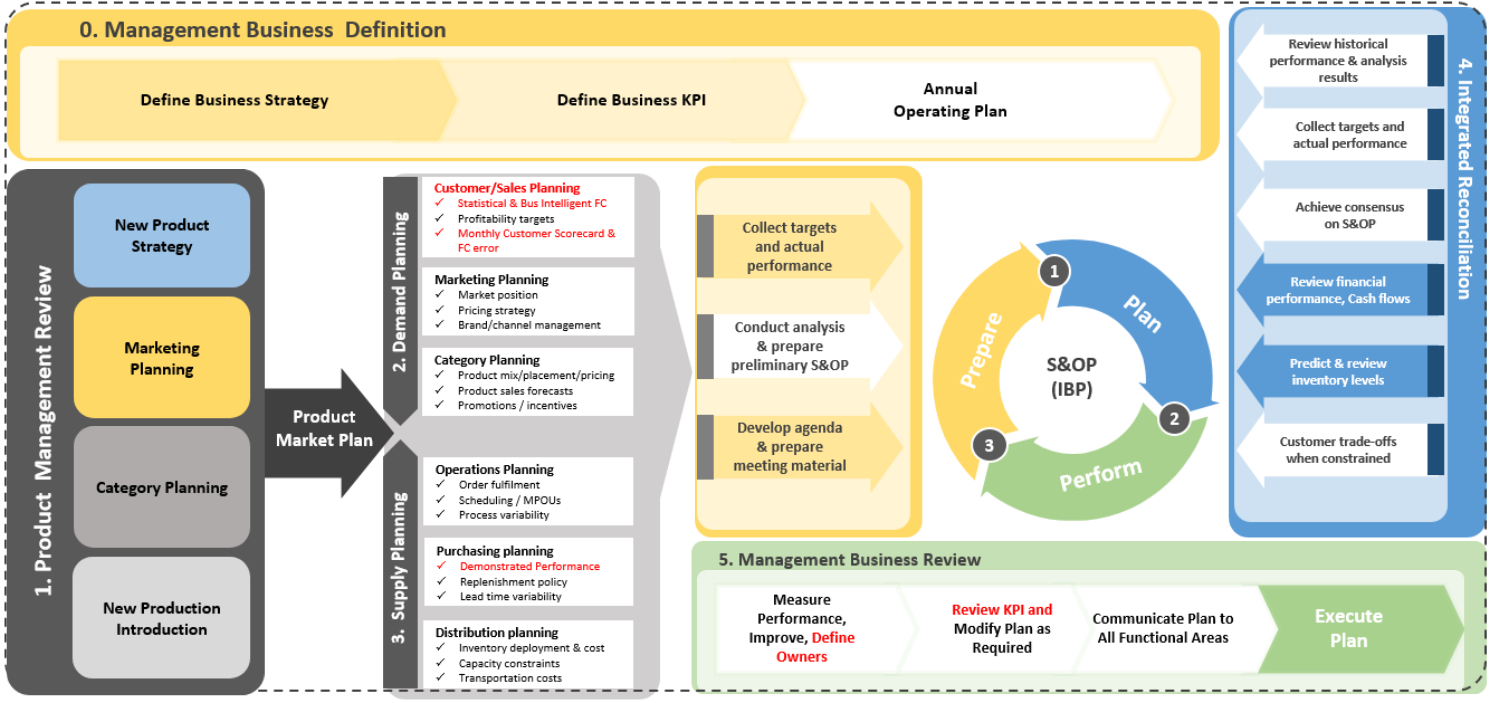

What Is Sales And Operations Planning S Op Plex Demandcaster

Aggregate Planning Strategy Organization Levels System Examples Model Type Company System

Capacity Management

3 Types Of Capacity Planning Strategies Valq

Capacity Planning What Is It And How Do I Implement It Projectmanager Com

Capacity Planning What Is It And How Do I Implement It Projectmanager Com

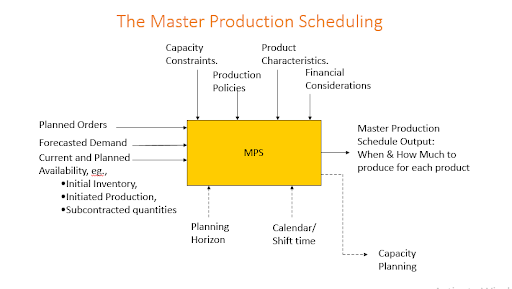

Inventory Management 101 The Master Production Schedule Mps Explained Optipro Software

What An Effective Capacity Planning Process Looks Like In 21

Capacity Planning In Project Management 4 Vital Success Factors Update 21

3 Types Of Capacity Planning Strategies Valq

Study Of Manufacturing System Capacity Planning Control Steps In Capacity Planning Measuring Demand Capacity Yield Management

/nissan-expands-production-capacity-at-iwaki-plant-72515647-5b009db3312834003775dbb0.jpg)

Capacity Requirements Planning Crp Definition

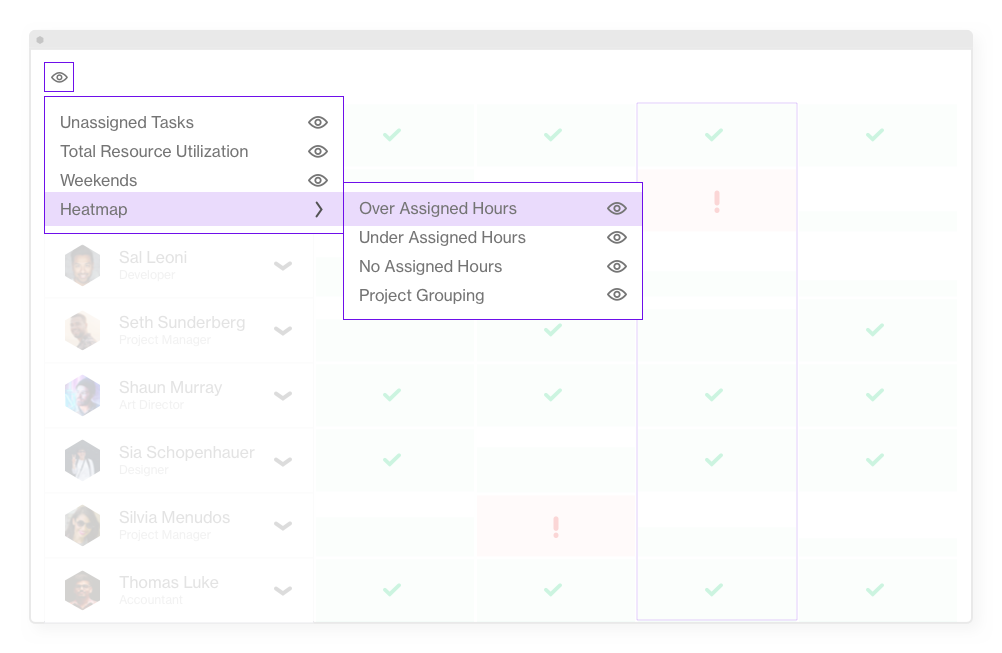

Capacity Planning For Project Managers How To Plan Your Team S Time

Capacity Planning An Overview Sciencedirect Topics

Ready To Upgrade Your S Op Process For Industry 4 0

What An Effective Capacity Planning Process Looks Like In 21

Chapter 6 Demand Management Dp C Chapter 6 Ppt Download

Production Planning Definition Objectives Need Types Importance

Page 2 Concept Check Questions Please Answer Chegg Com

Basics Of Supply Chain Management Ppt Video Online Download

Iteration Planning Scaled Agile Framework

Capacity Planning Meaning Classification And Its Goals

1

Capacity Planning In Project Management 4 Vital Success Factors Update 21

Capacity Planning Everything You Need To Know Clicktime

Understanding Itil Service Design Lucidchart Blog

1

Implementing A Sales Operations Planning S Op Process Plex Demandcaster

Living With Covid Plan What Is In Each Of The Five Levels

Capacity Planning Everything You Need To Know Clicktime

3 Types Of Capacity Planning Strategies Valq

How To Calculate Production Capacity Of A Factory

Module 5 Capacity Planning Pdf Inventory Operations Management

Capacity Planning 3 Methods How To Implement Them Optimoroute

Capacity Planning Everything You Need To Know Clicktime

Capacity Utilization Definition Example And Economic Significance

Capacity Planning In Project Management 4 Vital Success Factors Update 21

What Is Capacity Management Role In Planning Marketing91

What An Effective Capacity Planning Process Looks Like In 21

Capacity Planning

Study Of Manufacturing System Capacity Planning Control Steps In Capacity Planning Measuring Demand Capacity Yield Management

Capacity Planning In Project Management 4 Vital Success Factors Update 21

What An Effective Capacity Planning Process Looks Like In 21

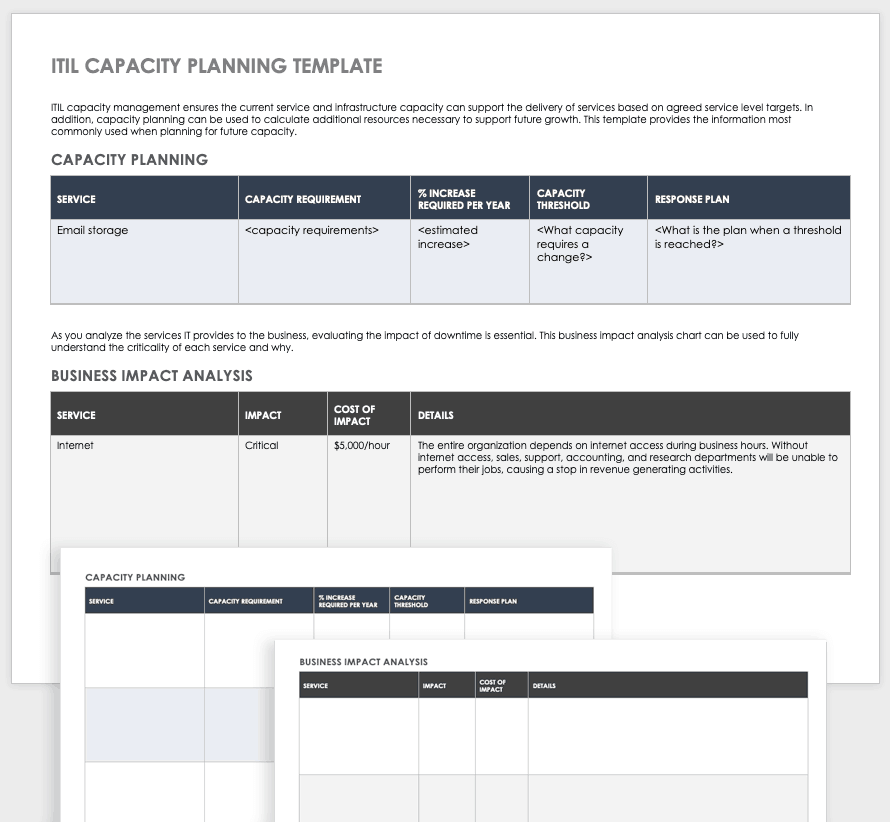

Free Itil Templates Smartsheet

Planning Production Capacity

Capacity Planning And Control Ppt Download

Public Health Preparedness Capabilities National Standards For State And Local Planning State And Local Readiness Cdc

What An Effective Capacity Planning Process Looks Like In 21

What Is Aggregate Planning 3 Strategies For Aggregate Production Planning

Planning Production Capacity

Production Planning Wikipedia

Set Sprint Capacity Azure Boards Microsoft Docs

Ultimate Guide To Resource Planning Smartsheet

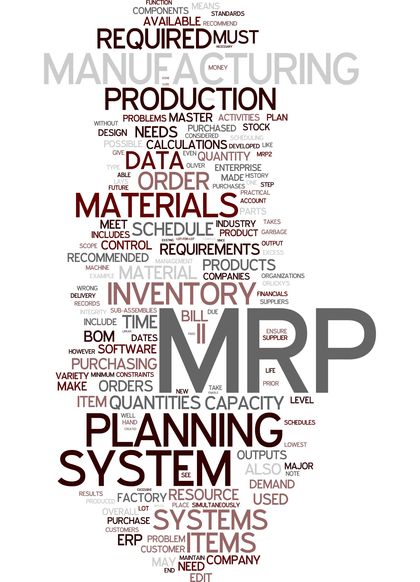

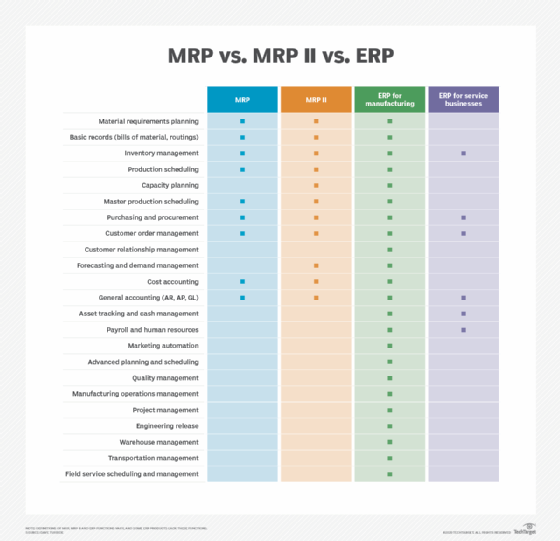

What Is Material Requirements Planning Mrp

Capacity Planning 3 Methods How To Implement Them Optimoroute

Achieving High Performance Low Cost Logistics Kearney

What Is Aggregate Planning 3 Strategies For Aggregate Production Planning

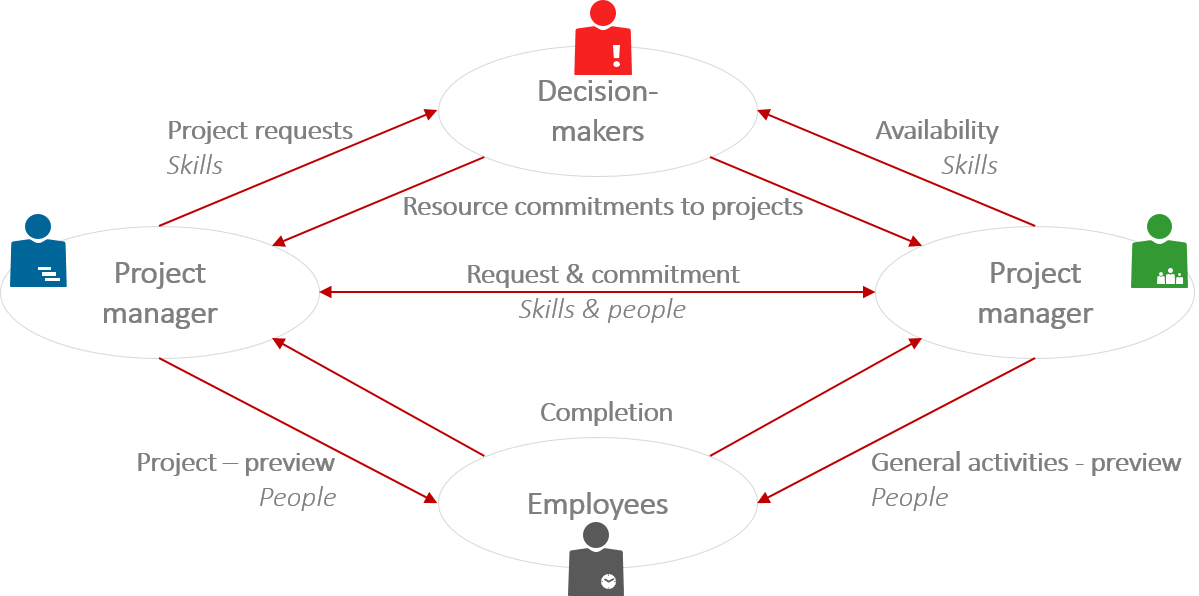

Project Resource Management Methods And Basics For Beginners Update 21

Operations Management Wikipedia

Capacity Planning 3 Methods How To Implement Them Optimoroute

Capacity Planning Springerlink

Production Planning An Overview Sciencedirect Topics

Capacity Planning Everything You Need To Know Clicktime

The Complete Beginners Guide To Agile Project Planning

Guidance For Implementing Covid 19 Prevention Strategies In The Context Of Varying Community Transmission Levels And Vaccination Coverage Mmwr

Production Planning An Overview Sciencedirect Topics

Capacity Planning Process 4 Overall Capacity Planning Process The Download Scientific Diagram

Capacity Building Wikipedia

Data Model And Hierarchy Targetprocess Enterprise Agility Solution

Myclass Dau Edu cswebdav Xid 4 1

Difference Between Resource Planning And Capacity Planning

Capacity Management Objectives Roles Concepts Mitsm

Module 5 Capacity Planning Pdf Inventory Operations Management

Demand Capacity Modelling And Covid 19 Disease Identifying Themes For Future Nhs Planning Pandit Anaesthesia Wiley Online Library

Everything You Need To Know About Material Requirements Planning Mrp Smartsheet

Capacity Planning Everything You Need To Know Opensense Labs

Capacity Planning Everything You Need To Know Clicktime

Capacity Planning Everything You Need To Know Opensense Labs

Capacity Planning What Is It And How Do I Implement It Projectmanager Com

Set Sprint Capacity Azure Boards Microsoft Docs

0 件のコメント:

コメントを投稿